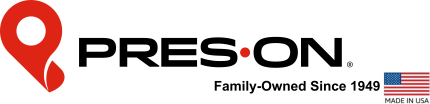

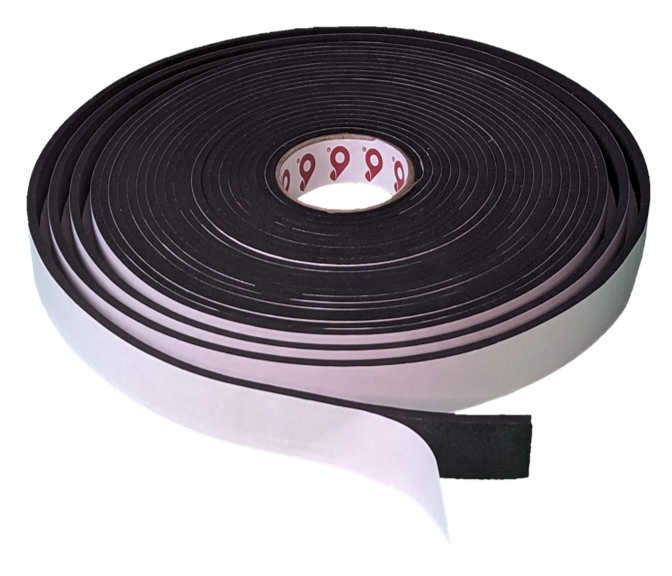

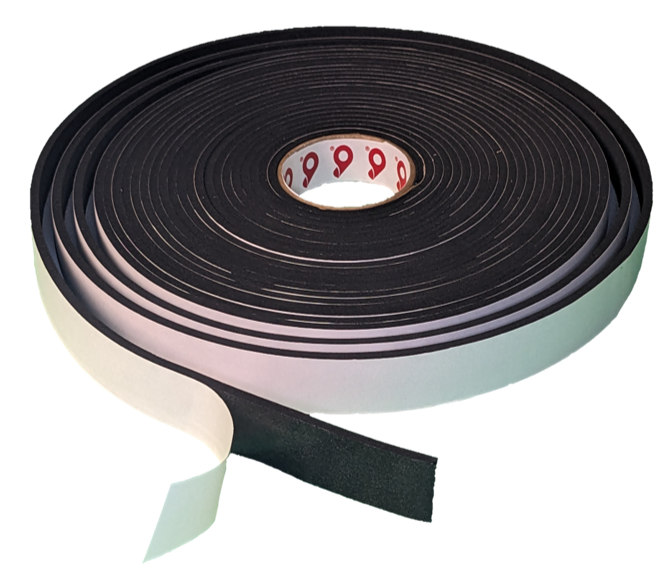

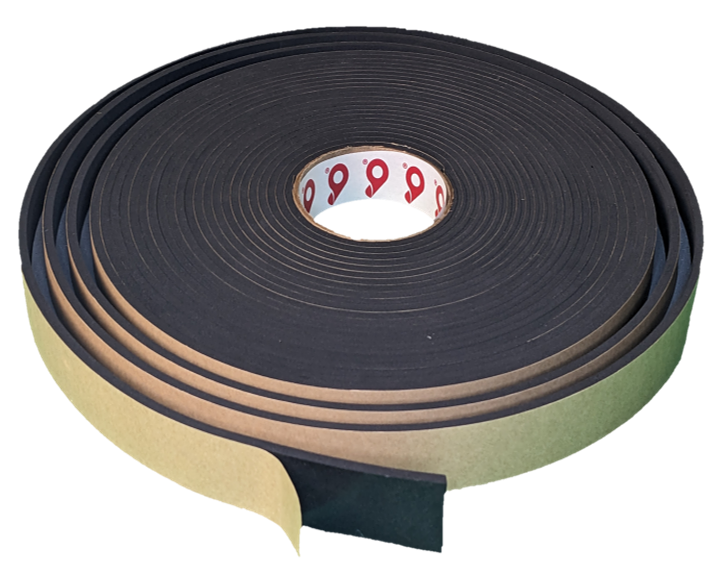

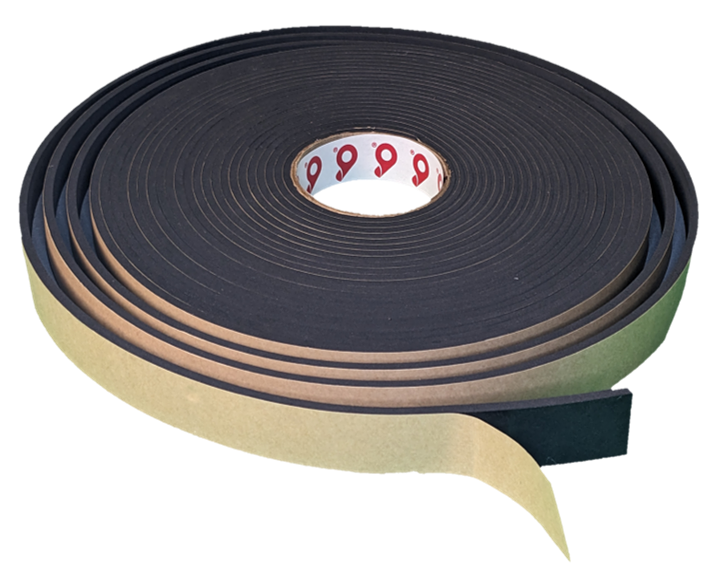

Neoprene / EPDM blend Foam Tape. Closed cell soft, black, with a smooth surface. Also known as Blended EPDM foam…

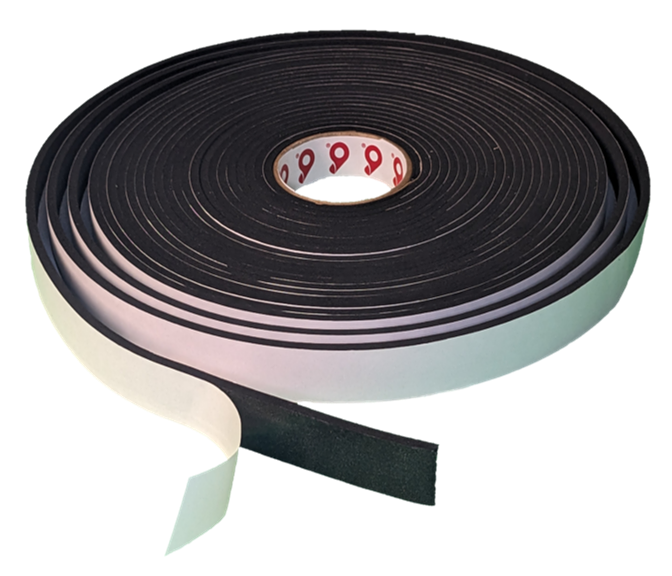

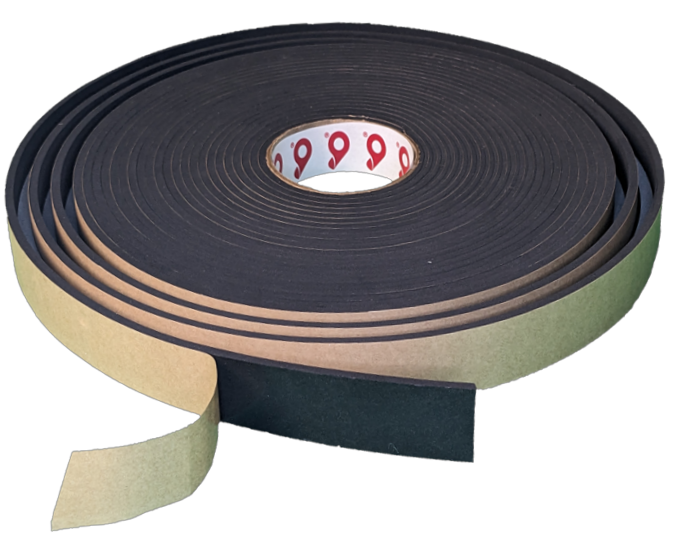

Nitrile Blend Foam Tape. Closed cell soft, black, with a smooth surface. Insulating, sound absorbing, UL, flame and smoke rated…

Neoprene / EPDM blend Foam Tape. Closed cell soft, black, with a smooth surface. Durable industrial strength foam with an…

Neoprene / EPDM blend Foam Tape. Closed cell medium, black, with a smooth surface. Durable industrial strength foam with an…

Neoprene / EPDM blend Foam Tape. Closed cell firm, black, with a smooth surface. Firm with durable industrial strength foam…

EPDM Foam Tape. Closed cell medium, black, with a smooth surface. Great quality with excellent UV and temperature resistance foam…

EPDM Foam Tape. Closed cell soft, black, with a smooth surface. Great quality with excellent UV and temperature resistance foam…

Custom adhesive coated products. Pres-On has the ability to adhesive coat a variety of custom materials. If you are looking…

EPDM Foam Tape. Closed cell soft, black, with a smooth surface. Great quality with excellent UV and temperature resistance foam…

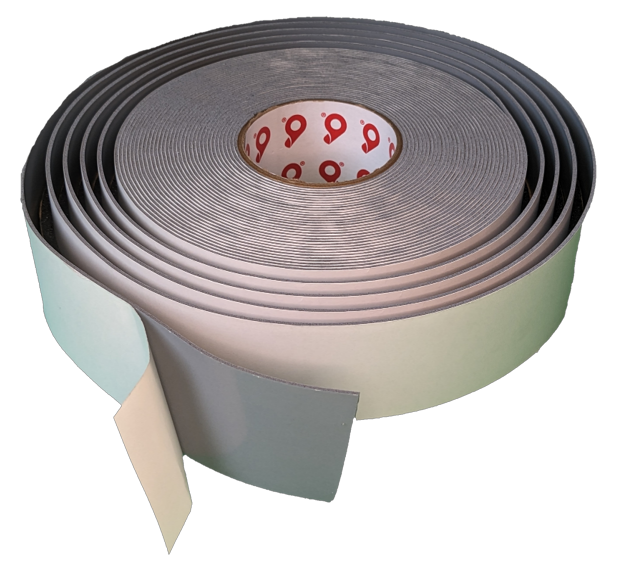

Silicone Foam Tape. Open/Closed cell medium, black, gray, or red, with a smooth skin surface. High temperature, corrosion, flame, UV…

100% Neoprene Foam Tape. Closed cell soft, black, with a smooth surface. Best quality neoprene foam with an industry leading…